12B/13B, North Building of Pacific Square, No.331, Jiahe Road, Siming District, Xiamen, Fujian, China. 361001

+86-592-5065811

+8615160739809

Material: Calacatta White Marble Column Skin Tiles

Size:H=100,200,240cm etc.D=30,50,60,75cm, etc.

Thickness:20,30,40,50mm

Surface: Polished

MOQ: 50 SQM

Brand: MQ STONE

Calacatta White Marble Column Cladding Tiles For Hotel and Villa Projects

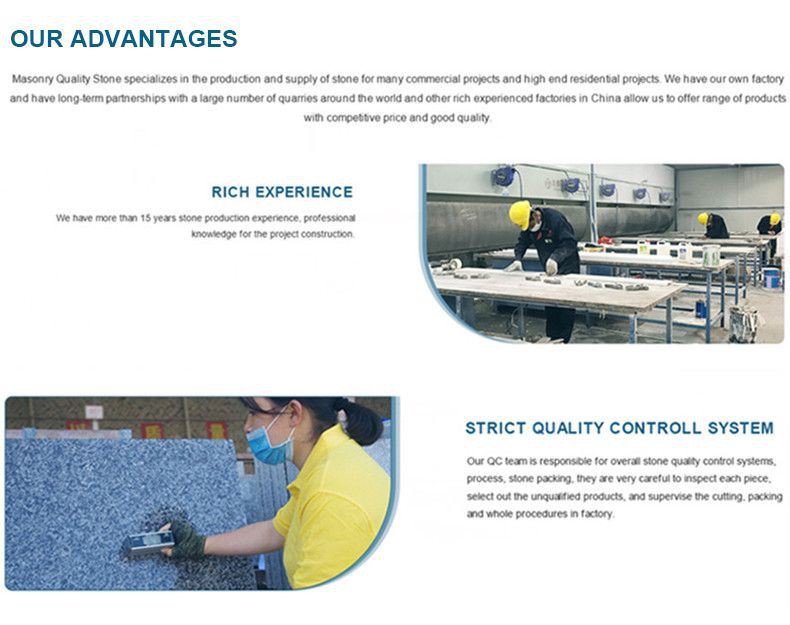

MQ STONE designs and manufactures custom marble columns, granite columns, solid columns or hollow columns, stone column cladding tiles, stone column skin, and cover tiles for interior and external architecture. We work with a wide range of selective clientele on custom marble and natural stone columns for high-end office, residential, and commercial buildings.

For millennia, Calacatta Marble Column Cladding and other materials such as travertine or limestone have graced the finest rooms and buildings. Natural stone columns are still preferred for their beauty, durability, and grandeur, even when contemporary construction techniques make them a luxury rather than a necessity.

Our staff creates Calacatta Marble Column Claddings Covers for clients all over the world, as well as column shafts, bases, and capitals in our Italian workshop, and transports columns to any worldwide location.

Calacatta Marble column facades have graced many of the most imposing buildings in history, from the temples of ancient Rome to the most modern residential and commercial buildings. Calacatta Marble Column Veneer Panel is the perfect material for the facades of prestige projects. Calacatta White Column Covering combines low-maintenance durability and fire resistance with natural beauty and elegance that synthetic facades cannot match.

| Item | low price marble column, granite column cover tiles |

| Material | 100% natural material(marble, granite, sandstone, stone, limestone, etc.) |

| Shape | Square, round, others |

| Size | H=100,200,240cm etc.D=30,50,60,75cm, etc. |

| customized sizes. | |

| style | Solid column, hollow column, solid pillar, hollow pillar. |

| Position | Interior and outdoor building decoration, decoration for Hotels, Square, Plaza, Gardens, Villadom, Church, Temple, etc. |

| Payment terms | T/T. |

| MOQ | 10sets. |

| Packing | wooden case. |

| Delivery time | depends on order quantity. |

| Quality standard | export standard. |

FAQ

The Process of Making Stone Columns or Column Covers?

Crushing stone and gravel results in stone columns. The particles are then put in position using a vibrator. To begin the operation, vertical holes are dug in the ground. The holes are subsequently filled with compact gravel and stone particles. This phase is critical because it aids in the strengthening of the surrounding poor ground. The diameter of the column can be preferred. More stones just need to be shoved in to accomplish this. The stones were then put in place by vibrations. The operation is repeated until the desired diameter is reached.